As the cold winter months approach, ensuring your boiler is in good working condition is important.

Winter is Here is Your Boiler Ready?

Don’t wait until it’s freezing outside to realize your boiler needs maintenance or repairs. Stay warm and cozy this winter by ensuring your boiler is ready to keep you comfortable.

Table of Contents

What is a Boiler?

It is a crucial component of many heating systems and hot water systems, providing warmth and comfort to homes and businesses alike. This appliance is responsible for generating heat through the combustion of fuel, such as gas, oil, or biomass, and then transferring that heat to water to produce steam or hot water.

Boilers come in a variety of types, including gas, oil, electric, and biomass, each with its own set of advantages and considerations.

With their importance in providing heating and hot water, understanding the function and operation of a boiler is essential for anyone relying on this technology for comfort and livelihood.

Check Your Boiler for Winter

As the colder months approach, check your boiler to ensure it is in proper working condition is essential. Neglecting maintenance can lead to potential safety risks, such as gas leaks and carbon monoxide poisoning.

A well-functioning unit is crucial during winter, as it provides heating and hot water for a comfortable home environment.

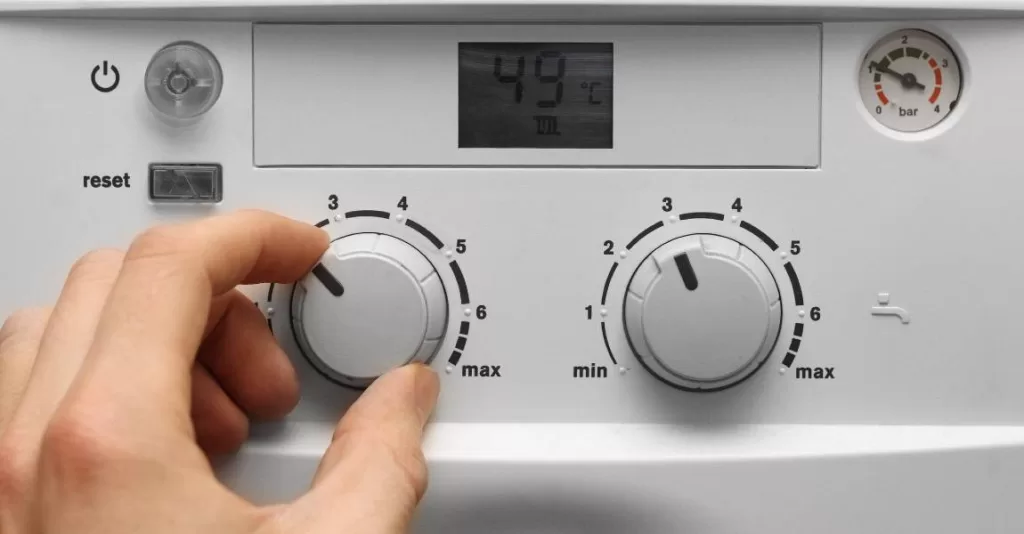

When inspecting the unit, key components to check include the heating elements, pressure levels, and thermostat settings. Ensuring that the heating system is functioning efficiently and safely is important.

To perform a winter check, schedule professional maintenance to inspect and service the unit thoroughly. DIY tasks such as checking for leaks and ensuring proper ventilation should be performed regularly.

Regular annual maintenance can save costs by preventing costly repairs and improving energy efficiency.

An efficiently running system also has a positive environmental impact by reducing energy consumption and emissions.

Checking your boiler for winter is crucial for safety, comfort, and cost savings. Following a boiler maintenance checklist and ensuring energy efficiency; you can enjoy the benefits of a well-maintained heating system throughout the colder months.

Energy Bills

As the winter season approaches, many homeowners are concerned about its impact on their energy bills.

One of the major contributors to higher energy bills during the colder months is the cost of heating the home. This is often reflected in the increased usage of boilers, which are essential for maintaining a comfortable indoor temperature.

We will explore the factors that affect costs in winter and discuss strategies for managing and reducing heating bills.

Why Is It Important to Check Your Boiler for Winter?

As winter approaches, ensure your boiler is in top condition to provide heat efficiently during the colder months is crucial. Neglecting boiler maintenance duties can lead to potential risks such as carbon monoxide leaks, inefficient heating, and higher energy bills. A well-functioning system ensures a warm and comfortable home and reduces the risk of breakdowns and costly repairs.

Key components that should be inspected, include the heating elements, pressure levels, pressure gauge, and thermostat settings. These components must be in optimal condition to ensure it operates efficiently and safely.

- To perform a winter system check, it is recommended to schedule professional maintenance to inspect and service the system thoroughly.

- DIY tasks such as checking for leaks, ensuring proper ventilation and cleaning the unit can contribute to its efficient functioning.

- Annual service can result in cost savings through maximum efficiency and reduced risk of breakdowns. Well-maintained boilers also have a positive environmental impact by minimizing energy consumption and emissions.

Conducting an annual boiler service and maintenance checklist is essential for winter preparation, ensuring a well-functioning heating system, and promoting energy efficiency and environmental sustainability. boiler maintenance tips for homeowners can help identify potential issues before they become costly repairs. Regularly checking the pressure and topping up the system can prevent breakdowns during the cold months. Additionally, ensuring that all vents are clear will improve efficiency and safety in your home heating system.

Understanding these factors can help homeowners make informed decisions about their heating systems and take steps to minimize the financial impact of winter on their energy bills.

How Can You Reduce Your Energy Bills in the Winter Months?

1. Seal Drafts: Use weather stripping or caulking to seal any drafts around windows and doors to prevent heat from escaping. This helps maintain a comfortable indoor temperature and reduces the need for constant heating, ultimately lowering energy bills.

2. Lower the Thermostat: Lowering your thermostat by just a few degrees can significantly impact your energy consumption. Dress warmly and use blankets to stay comfortable without cranking up the heat.

3. Use Energy-Efficient Appliances: Consider using energy-efficient space heaters, boilers, and heat pumps to reduce overall energy consumption. Upgrading to energy-efficient appliances can result in long-term cost savings on your energy bills.

4. Maximize Natural Sunlight: Open curtains and blinds to let natural sunlight in during daylight hours. This can naturally warm up your home and reduce the need for additional heating.

5. Annual Boiler Tune-Ups: Regular maintenance and tune-ups for your system can improve its efficiency and reduce energy waste. A well-maintained system will heat your home more effectively and help lower energy costs.

You can significantly reduce your monthly energy bills by implementing these winter energy-saving tips. Sealing drafts, lowering the thermostat, using energy-efficient appliances, maximizing natural sunlight, and scheduling annual boiler tune-ups all contribute to a more energy-efficient home and lower overall energy expense during the winter months.

Boiler Pressure

Boiler pressure is a critical factor in the operation of any steam system. It refers to the force exerted by the steam inside the unit, and ensuring that the pressure remains optimal for efficient and safe operation is necessary.

Improper boiler pressure can lead to decreased energy efficiency, higher fuel consumption, and, in extreme cases, even boiler failure. Monitoring and maintaining the correct boiler pressure is essential for the overall functionality and safety of the system.

In this section, we will explore the importance of boiler pressure, how to measure and regulate it, and the potential consequences of having either too high or too low pressure. We will also discuss the various methods and tools available for controlling the boiler pressure to ensure smooth and trouble-free operation.

What Does the Pressure Gauge Tell Me About My Boiler Health?

The pressure gauge on your system provides important information about its health. It indicates the pressure of the water inside the boiler and helps you monitor if it operates at the correct pressure.

A normal reading for a water pressure gauge on a gas boiler should be around 1 to 1.5 bar when the system is cold. If the pressure gauge is too high or too low, it can indicate potential issues.

Having boiler pressure that is too high can lead to leaks, overheating, and, in extreme cases, the risk of an explosion. On the other hand, having a pressure that is too low can result in inefficient heating, a lockout, or even damage to the system.

Monitoring the pressure gauge regularly is important to ensure it is functioning safely and efficiently.

If the pressure gauge indicates a rise in boiler pressure, it is essential to consult the manual for specific instructions on adjusting the pressure.

This may involve:

- bleeding the radiators

- adjusting the filling loop

- Contact a qualified registered engineer for assistance

Regularly monitoring and maintaining the correct boiler pressure is vital, especially during cold weather, to ensure the safety and efficiency of the heating system.

What Should I Do If My Boiler Pressure Falls Too Low?

If your pressure falls too low; you can repressurize it using the filling loop and adjusting the valves.

First, locate the filling loop, usually located underneath it.

Connect the filling loop to the valves and slowly open them to allow water to flow into the system.

Keep an eye on the pressure gauge and stop when it reaches around 1.5 bar, the recommended pressure.

Before repressurizing, check for potential issues such as a failed expansion vessel, blocked pressure sensor, or frozen pipes, and address these issues accordingly.

If you are unsure how to repressurize your boiler, refer to the manufacturer’s guide for specific instructions.

It is important to exercise common sense and follow the manufacturer’s guidelines to ensure your boiler’s safety and proper pressurization.

Central Heating System

Preparing your central heating system for Winter is crucial to ensure it runs efficiently and effectively when needed. Here are the steps to prepare your heating system for the cold:

1. Check the boiler: Ensure that your boiler is in good working condition by scheduling a service with a qualified engineer. This will help identify any issues and ensure it is running efficiently.

2. Insulate pipes: Insulating your pipes with foam insulation can help prevent them from freezing during Winter, reducing the risk of burst pipes.

3. Bleed radiators: Bleeding your radiators will remove air pockets, allowing them to heat up more effectively and evenly.

Preparing your heating system for Winter weather has several benefits, including lower energy bills, a more comfortable living environment, and reduced risk of boiler breakdowns.

By maintaining your heating system, you can also prolong the lifespan of your boiler and reduce the likelihood of needing a costly replacement.

If your unit is ineffective despite maintenance, it may be time to consider a new boiler replacement to ensure a reliable and efficient heating system throughout the Winter months. Effective central heating system maintenance is key to staying warm and comfortable during the colder months.

Hot Water Supply

Hot water supply systems play a crucial role in residential, commercial, and industrial environments, providing the necessary hot water for various purposes such as bathing, cleaning, and heating. Boilers are essential components of these systems, serving as the main heat source to ensure a constant hot water supply.

Understanding the different types of boilers and their functionalities is important for ensuring an efficient and reliable hot water supply.

What Should I Do If I Notice a Dip in My Hot Water Supply During The Colder Months?

If you notice a dip in your hot water supply during the colder months, there are several possible causes to consider.

- One common issue is air trapped in the system, which can cause fluctuations in hot water temperature. This can be addressed by bleeding the radiators to release any trapped air.

- Another cause could be a drop in the thermostat setting, so make sure to check and adjust it accordingly.

- Uninsulated pipes can lead to heat loss, so consider insulating your pipes to maintain a consistent hot water supply.

To troubleshoot and fix the issue, start bleeding your radiators to release any trapped air.

Next, check for any leaks in the system that could be causing the dip in the hot water supply.

If you cannot identify or fix the issue on your own, you may need to contact a professional for further assistance.

A professional can thoroughly inspect your hot water system and address any issues that may be causing the dip in the hot water supply during the colder months. Taking these steps can help ensure that you have a consistent and reliable hot water supply throughout the winter.

Filling Loop and Combi Boilers

To top up the water pressure in a combi boiler, you will need to use the filling loop.

When the pressure drops, locate the filling loop connection on the boiler – this is usually located underneath the boiler.

There are two valves on either end of the filling loop. Slowly open these valves to allow water to enter the system. As you do this, keep an eye on the pressure gauge on the boiler.

You should aim to increase the pressure to around 1 to 1.5 bar, although you should consult your boiler’s manual for the recommended pressure level. Once the pressure is at the correct level, close the valves on the filling loop. Do this slowly to prevent sudden pressure increases.

It’s important to note that over-pressurizing the system can cause damage, so checking the pressure gauge as you go is essential.

By following these steps, you can efficiently use the filling loop to top up the water pressure in a combi boiler.

Freezing Pipes

Preventing freezing pipes is crucial, especially during the cold winter months. To prevent freezing pipes, it is important to take the following steps:

1. Check and insulate all pipes in your home, especially those located in unheated areas such as the attic, basement, and exterior walls.

2. Be sure to drain any outdoor water supply, including hoses and sprinkler systems, to prevent water from freezing and causing damage to the pipes.

3. Insulate your boiler pipes and condensate pipes to prevent them from freezing and causing a disruption to your heating system.

4. In the event that your pipes do freeze, it is important to safely thaw them using a hairdryer, heating pad, or towels soaked in hot water. Never use an open flame or high-heat device to thaw frozen pipes.

5. After thawing the frozen pipes, check for leaks and any potential damage that may have occurred. It’s important to promptly address any leaks or damage to prevent further issues.

By following these steps, you can effectively prevent freezing pipes and avoid potential damage to your home’s plumbing system.

Safety Devices &

Relief Valves, Slowly Warming the Boiler and Dealing with Frozen Pipes.

Before restarting the unit, it is crucial to check all safety devices and relief valves to ensure they operate correctly. This includes inspecting safety devices such as low water cut-off switches, safety release valves, and pressure control devices.

It is important to verify that relief valves are not blocked and can release pressure as needed for safe operation.

When restarting the unit, it is vital to warm the system slowly to allow for controlled expansion of the metals. This reduces stress on the boiler, prolongs its lifespan, and ensures safe and efficient operation. Rapidly heating it can cause thermal shock, leading to damage and potential safety hazards.

In the event of encountering frozen pipes, it is necessary to open release valves downstream of the frozen pipe to release any built-up steam pressure safely. This helps prevent potential damage or rupturing of the pipes due to the increased pressure from the frozen blockage. It is also important to thaw the frozen pipes carefully to avoid further damage or safety risks.

By following these procedures for safety devices, relief valves, slowly warming the boiler, and addressing frozen pipes, you can maintain the safety and efficiency of the boiler system.

Conclusion

In conclusion, ensuring your boiler is ready for winter and is crucial for maintaining a comfortable and safe living environment. Don’t wait until it’s too late – schedule a boiler inspection and maintenance service today to ensure it runs efficiently and effectively throughout the cold season.